cuelathe

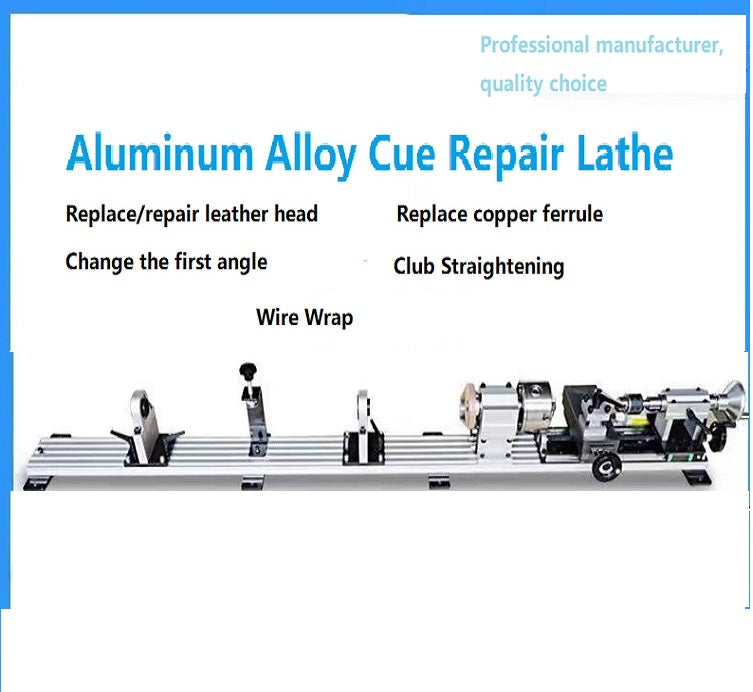

Aluminum alloy single head cue repair lathe, billiard cue repair lathe, billiard cue repair machine, billiard supplies

Aluminum alloy single head cue repair lathe, billiard cue repair lathe, billiard cue repair machine, billiard supplies

Couldn't load pickup availability

Aluminum alloy single-head double-track cue lathe, with 3-claw 100 chuck, fast clamping, high precision.

Aluminum alloy slide plate, one-button fast sliding and locking.

Aluminum metal workbench, all-metal rear hanging. The bracket rear hanging can be adjusted for telescopic use, and the rear hanging can be adjusted in length.

High-power speed-regulating motor, strong power.

Replace manual rod trimming, efficient and fast.

Small appearance, high-end, a must-have in the ball room.

[Material]: The billiard cue repair machine is made of thickened aluminum alloy plate, and the double tail bearing seat, tail seat and spindle seat are all made of aluminum;

[Motor]: The pool cue repair machine is equipped with a 550W high-power brushless motor, voltage of 110V, 60hz, American standard plug, speed 0-3000r/min, forward and reverse stepless speed control box, strong power, stable operation, low noise, long service life;

[Spindle]: The spindle through hole of the pool cue lathe is 20mm, and it adopts a 100mm linkage three-jaw chuck with an accuracy of 0.001-0.002 inches. It adopts a double tail drag bearing seat design with good stability and high precision. The middle drag plate and tail seat can move left and right on the guide rail to a limited extent;

[Tool holder]: The pool cue lathe machine is equipped with a two-station ordinary tool holder as standard, and can also be equipped with an aluminum American-style quick-change tool holder, which features fast switching, precise positioning, wear resistance and lightness;

[Tailstock]: The pool cue repair lathe machine adopts a high-precision adjustable tailstock and is equipped with a 1.5-13mm drill chuck, which ensures precise centering and more stable drilling;

【Machine Function】: The pool cue repairing machine is mainly used for the maintenance and repair of various cues, such as replacing leather heads, replacing copper hoops, replacing first angles, making copper hoops and first angles, polishing and grinding of cues, etc.

Motor Power: 550W

Voltage:110V/220V

Frequency: 50Hz/60Hz

Continuously Variable: 0--3000(Kw/rpm)

G.W/N.W: 44.8kg/26.8kg

Size:1700mm*270mm*270mm

Packing Dimension:1750mm*400mm*350mm

Share